We are Manufacturer, Supplier, Exporter of: Shell & Tube Water Oil Coolers from Belgaum, Karnataka, India.

Though the specified capacity & stroke of the jacks are designed for maximum safe working, we recommend to use the jacks for 85% of its rated capacity & stroke as safe working practice and for long life of the jacks.

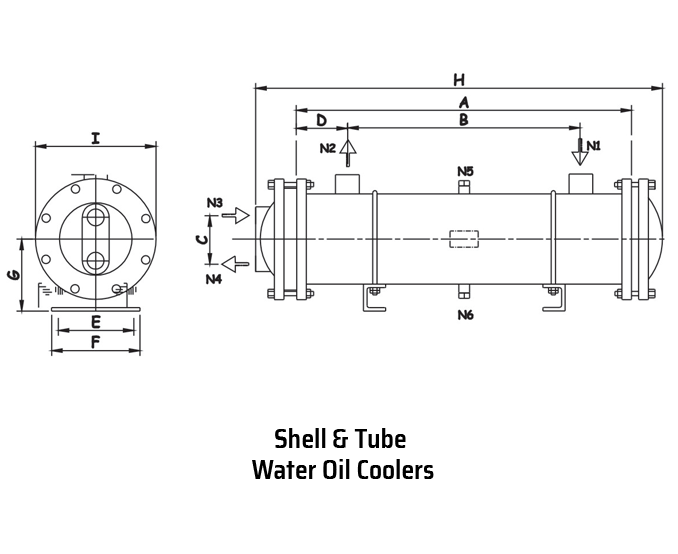

Technical Specification :

|

Model

|

HP

|

KW

|

Kcal / Hr

|

LPM

|

Size Inch

|

A

mm |

B

mm |

C

mm |

D mm |

E mm |

F mm |

G mm |

H mm |

I mm |

N1 inch |

N2 inch |

N3 inch |

N4 inch |

N5/N6 inch |

| POC 2 | 2 | 1.5 | 1400 | 15 | 4X18 | 432 | 290 | 58 | 71 | 114 | 150 | 120 | 525 | 180 | 3/4"BSP | 3/4"BSP | 1"BSP | 1"BSP | 1/4"BSP |

| POC 3 | 2.0 | 2.0 | 2200 | 20 | 4X20 | 483 | 335 | 58 | 74 | 114 | 150 | 120 | 576 | 180 | 3/4"BSP | 3/4"BSP | 1"BSP | 1"BSP | 1/4"BSP |

| POC 5 | 5 | 3.0 | 3000 | 30 | 4X24 | 584 | 434 | 58 | 75 | 114 | 150 | 120 | 667 | 180 | 3/4"BSP | 3/4"BSP | 1"BSP | 1"BSP | 1/4"BSP |

| POC 7.5 | 7.5 | 5.0 | 4750 | 50 | 4X30 | 737 | 587 | 58 | 75 | 114 | 150 | 120 | 830 | 180 | 3/4"BSP | 3/4"BSP | 1"BSP | 1"BSP | 1/4"BSP |

| POC 10 | 10 | 7.0 | 6000 | 60 | 5X24 | 584 | 434 | 65 | 74 | 141 | 180 | 132 | 687 | 202 | 1"BSP | 1 1/4"BSP | 1 1/4"BSP | 1 1/4"BSP | 1 1/4"BSP |

| POC 15 | 15 | 10 | 9500 | 80 | 5X30 | 737 | 587 | 65 | 74 | 141 | 180 | 132 | 840 | 202 | 1"BSP | 1 1/4"BSP | 1 1/4"BSP | 1 1/4"BSP | 1 1/4"BSP |

| POC 20 | 20 | 14 | 13000 | 125 | 6X24 | 584 | 415 | 90 | 85 | 165 | 210 | 148 | 685 | 228 | 1.5"NB | 1.5"NB | 1.5"BSP | 1.5"BSP | 1/4"BSP |

| POC 25 | 25 | 18 | 17500 | 150 | 6X30 | 737 | 567 | 90 | 85 | 165 | 210 | 148 | 838 | 228 | 1.5"NB | 1.5"NB | 1.5"BSP | 1.5"BSP | 1/4"BSP |

| POC 30 | 30 | 22 | 23500 | 200 | 8X24 | 584 | 414 | 115 | 85 | 220 | 275 | 170 | 713 | 282 | 1.5"NB | 1.5"NB | 2"BSP | 2"BSP | 3/8"BSP |

| POC 40 | 40 | 28 | 31000 | 250 | 8X24 | 584 | 414 | 115 | 85 | 220 | 275 | 170 | 713 | 282 | 1.5"NB | 1.5"NB | 2"BSP | 2"BSP | 3/8"BSP |

| POC 50 | 50 | 36 | 34000 | 300 | 8X30 | 737 | 567 | 115 | 85 | 220 | 275 | 170 | 866 | 282 | 1.5"NB | 1.5"NB | 2"BSP | 2"BSP | 3/8"BSP |

| POC 60 | 60 | 44 | 37500 | 350 | 8X36 | 889 | 669 | 115 | 110 | 220 | 275 | 170 | 1018 | 282 | 2"NB | 2"NB | 2.5"BSP | 2.5"BSP | 3/8"BSP |

| POC 70 | 70 | 52 | 43750 | 400 | 8X42 | 1042 | 792 | 115 | 125 | 220 | 275 | 170 | 1171 | 282 | 2.5"NB | 2.5"NB | 2.5"BSP | 2.5"BSP | 3/8"BSP |

| POC 80 | 80 | 58 | 58000 | 450 | 8X48 | 1194 | 944 | 115 | 125 | 220 | 275 | 170 | 1323 | 282 | 2.5"NB | 2.5"NB | 2.5"BSP | 2.5"BSP | 3/8"BSP |

|

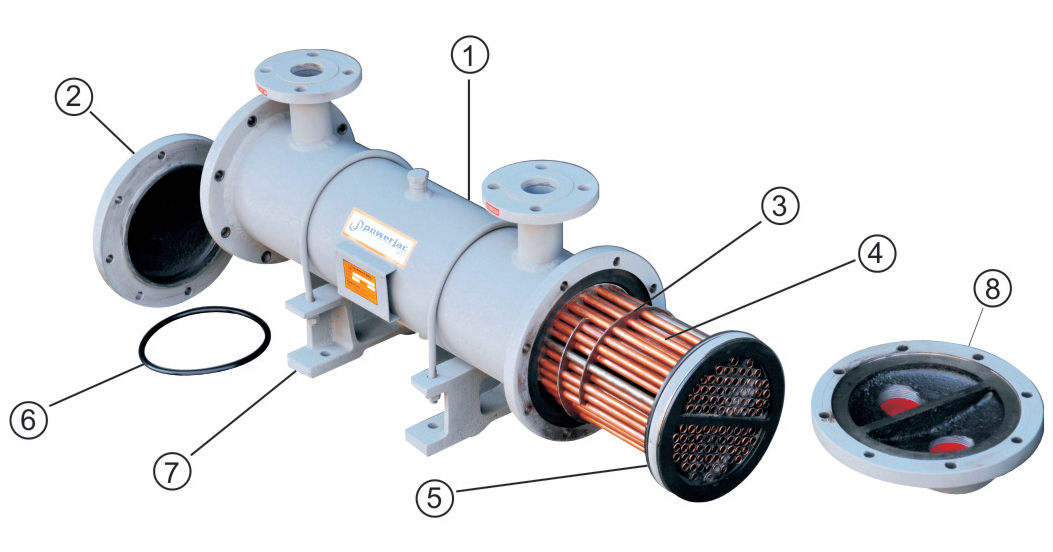

Part Name

|

Material

|

Construction

|

| SHELL | Carbon steel (Stainless steel Shell on request) | Steel Tube to accommodate the tube bundle |

| END COVER | Cast iron (Mild steel on request) | The End Covers are of bolted for removal of tube bundle from shell side for ease of replacement |

| BAFFLES | Carbon steel (Mild steel, Brass & Stainless steel on request) | Machine drilled and reamed accurately to maximize Thermal efficiency |

| TUBES | Copper (Brass, Stainless steel & Copper Nickle on request) | SB - 111 C - 12200 |

| Tube SHEET | Mild Steel (Brass & Stainless steel on request) | Tube Sheet plate in machined, drilled and reamed accurately to accommodate the tubes precisely |

| SEAL/'O' RING | Neoprene | To ensure high tightness and restrict any fluid contamination. easily replaceable |

| DRAIN PLUG | Mild Steel | Accurately Machined and threaded |

|

Part No.

|

Name

|

Construction

|

Description

|

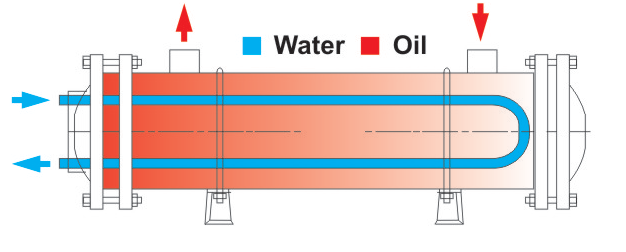

Shell Side

|

Tube Side

|

| 1 | Shell |

|

Fluid Circulated | Oil | Water |

| 2 | End Cover | No. of passes | One | Two | |

| 3 | Baffles | Design temperature oC | 100 | 50 | |

| 4 | Tubes | Design pressure Kg/Sq cm | 10 | 5 | |

| 5 | Tube Sheet | Hydro test pressure kg/Sq m | 15 | 7.5 | |

| 6 | Seal / 'O' Ring |  |

|||

| 7 | Mounting Feet | ||||

| 8 | Front Cover | ||||